Micro Mechanics Importance: Key Roles in Science and Technology

Updated On: November 13, 2025 by Aaron Connolly

Defining Micro Mechanics and Its Core Concepts

Micro mechanics digs into how materials act at tiny scales, where all those little parts interact to shape the bigger picture. It bridges the world of building blocks with the performance we notice in things like computer chips or airplane wings.

Distinction Between Micro and Macro Scale Mechanics

Traditional mechanics focuses on whole objects. A bridge bends under a heavy truck. Car engines churn out power. Those are macro scale things.

Micro mechanics flips the script. Instead of looking at the big stuff, it zooms in on what’s happening inside, at scales we can’t see without some serious magnification. Take carbon fibre—at the macro level, it’s strong and light. But up close, it’s a bunch of carbon threads glued together with plastic.

Here’s what really sets them apart:

- Scale: Micro mechanics looks at parts way smaller than the naked eye can spot.

- Approach: It studies the pieces, not just the whole.

- Purpose: The goal is to predict how these little parts team up to shape the big picture.

This actually matters a lot. Materials can act tough on the outside but hide weaknesses in tiny cracks. Micro mechanics lets us figure out those hidden details.

Engineers lean on this field to design smarter, tougher materials. They can test out new fibre mixes virtually, before committing to expensive prototypes.

Key Principles and Terminology

Micro mechanics has its own lingo. The representative volume element (RVE) stands for a small sample that captures what the material’s really like.

Homogenisation is about turning all those messy details into simple rules for the whole material. Imagine describing a forest by the average tree height, not by tracking every single branch.

Localisation does the opposite. It figures out what each tiny part feels when you push or pull on the whole thing.

Some key concepts:

- Constituents: The stuff you mix together.

- Phase: Each distinct material in the mix.

- Volume fraction: How much of each type you’ve got.

- Anisotropic: Properties shift depending on direction.

These ideas help engineers explain why materials act the way they do. Maybe a composite is strong along one axis but not another. Micro mechanics gets to the root of that by looking at how the parts are arranged.

Relationship with Nanomechanics

Nanomechanics dives even deeper than micro mechanics. While micro mechanics might use a strong microscope, nanomechanics zooms in on individual atoms and molecules.

Both fields actually work hand in hand in mechanical systems. Nanomechanics explains what goes down between atoms. Micro mechanics grabs that info and applies it to slightly bigger structures.

Nanotechnology needs both. If you’re designing a computer chip, you have to know how electrons move between atoms (that’s nanomechanics) and how tiny circuits act as a group (that’s micromechanics).

The scale progression looks like this:

- Nanomechanics: Atoms and molecules

- Micromechanics: Small groups and structures

- Macro mechanics: Full objects and systems

Modern tech usually spans all three levels. A phone screen depends on atomic-level properties, micro-scale circuits, and macro-scale strength. Engineers need to connect all those dots to build better stuff.

This kind of multi-scale thinking keeps pushing innovation in everything from medicine to aerospace.

Why Micro Mechanics Matters in Materials Science

Micro mechanics ties together what’s happening at the tiniest scales with the real-world performance we expect. It lets us figure out how cracks get started, why some metals bend instead of snapping, and how to build stronger stuff from scratch.

Linking Microstructure to Material Properties

Materials get their strength and character from interactions between atoms and tiny crystals. We can see how small flaws and boundaries change how the whole thing acts.

Take steel, for example. Its hardness comes from carbon atoms wedged between iron atoms. Micro mechanics helps us see why that matters.

Some key links:

- Grain size changes strength and flexibility.

- Crystal structure sets electrical properties.

- Defects can make weak spots that turn into failures.

- Chemical bonds set the limits on material performance.

When we dig into these tiny details, we start to understand why materials behave the way they do. Something might look smooth, but up close, it’s a wild landscape of microscopic features.

Those little features add up fast. They decide if a cable snaps or a phone screen shatters when it hits the ground.

Role in Materials Performance

Micro mechanics uncovers why materials sometimes fail before we expect. It points out the real triggers behind cracks, wear, and breakdowns.

Things we can predict:

- How long a material lasts under stress.

- Where cracks are likely to start and travel.

- Which areas might give out first.

- The temperature range for safe use.

Materials science runs simulations using this info, so we can test new designs without building costly prototypes every time.

Let’s say you’re making airplane parts. They need to survive millions of flights. Micro mechanics helps engineers spot trouble before it gets expensive.

Sometimes, we also find out why a material does better than expected. That can lead to cool upgrades without changing the basic ingredients.

Influence on Material Design

Modern materials often start with micro mechanics. We design the structure at the tiniest level, then scale up to get the properties we want.

Design tricks include:

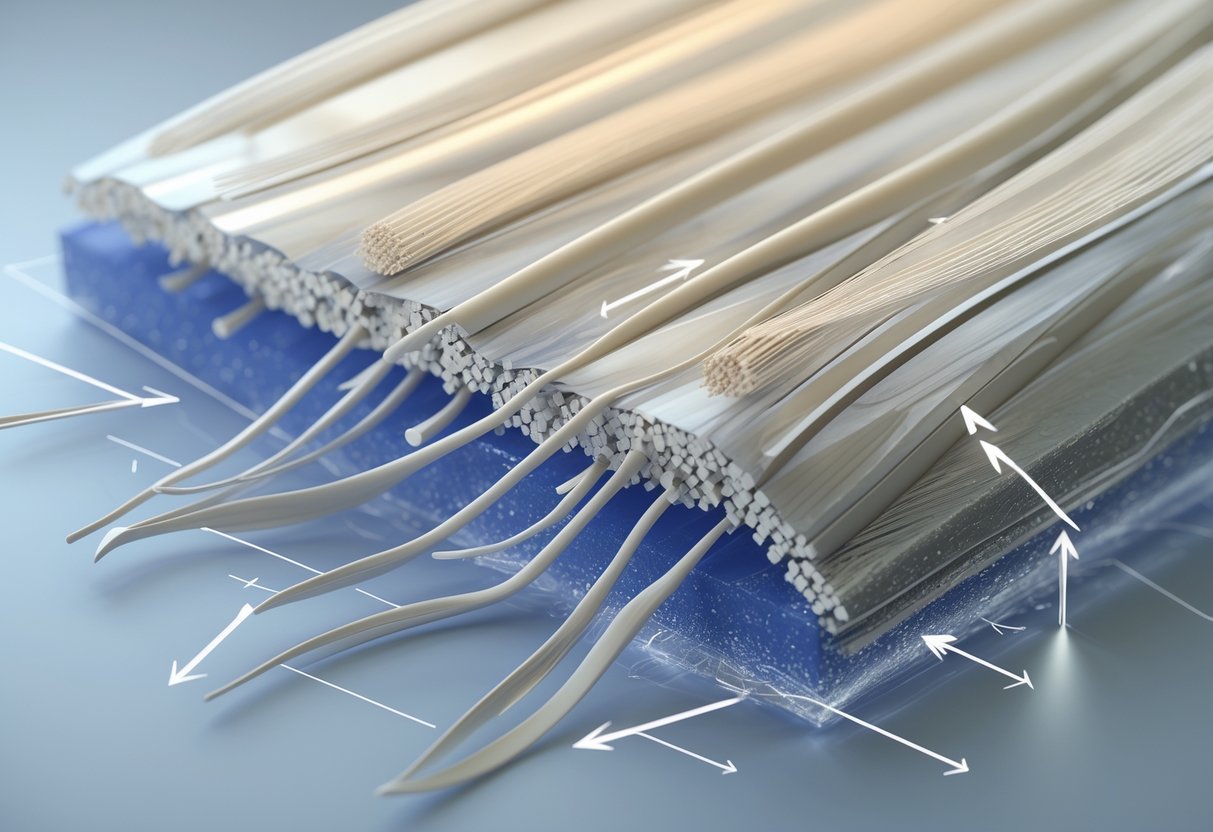

- Composite layering: Lining up fibres for max strength.

- Grain control: Tweaking crystal size during manufacturing.

- Defect engineering: Adding small, controlled flaws to prevent bigger disasters.

- Surface treatments: Changing just the outer layer’s properties.

This lets us make stuff nature never came up with. We can blend the best qualities of different materials into one.

Carbon fibre composites are a great example. Engineers arrange carbon threads in specific patterns, creating materials stronger than steel but way lighter.

Micro mechanics also helps us fix existing materials. Instead of swapping everything out, we can target the tiny features causing trouble.

Understanding Microstructures and Their Effects

The inside structure of a material controls how it holds up under stress. Tiny crystals and flaws can make or break performance. We use powerful microscopes to peek inside and predict how things will hold up in real life.

Crystal Structure and Phases

Crystal structure sets the basic rules for a material. Atoms line up in patterns that become the backbone of metals, ceramics, and composites.

One material can have different phases—each with its own crystal structure and properties. Steel, for example, has ferrite and pearlite phases. That mix gives it both strength and toughness.

Key features to watch:

- Grain size (usually 1-100 micrometers)

- Where phases are and how they’re arranged

- Which way crystals point

- Boundaries between grains

Grain size really matters. Smaller grains usually mean stronger material, since they stop cracks from spreading.

Temperature and processing change which phases pop up. Heat treatment can totally change a material’s structure, sometimes making something brittle into something tough.

Defects and Inhomogeneities

Every material has flaws—there’s no such thing as perfect. These microscopic defects often decide how and when a material fails.

Some common defects:

- Vacancies (missing atoms)

- Dislocations (misaligned atomic rows)

- Grain boundaries

- Impurities or bits of foreign material

Defects aren’t always bad. Sometimes, like with tiny precipitates, they actually make a material stronger by blocking movement. But unwanted defects, like voids, can really weaken things.

How you process a material changes the defect pattern. Quick cooling traps more defects. Heavy shaping introduces dislocations that can make a material tougher.

Where the defects are is just as important as what they are. If they clump together, you get weak spots. If they’re spread out, the material usually holds up better.

Imaging and Characterisation Techniques

Modern microscopes let us see microstructures in wild detail. Each technique shows a different side of the material.

Main imaging tools:

| Technique | Magnification | Best For |

|---|---|---|

| Optical microscopy | 25-2000× | Grain structure, phases |

| Scanning electron microscopy (SEM) | 100-500,000× | Surface detail, composition |

| Transmission electron microscopy (TEM) | 50,000-2,000,000× | Crystal defects, atomic structure |

Sample prep is key. We polish surfaces to a mirror shine and sometimes etch them to show grain boundaries. For electron microscopes, samples have to be super thin.

Each tool needs its own prep method. Optical microscopes want polished surfaces. SEM works best if you add a conductive coating. TEM needs samples thinner than a human hair.

These tools help us predict material behaviour before we build expensive prototypes. We can spot trouble spots and tweak processing to dodge them.

Mechanical Properties at the Microscale

Materials act differently at tiny scales than they do in bulk. Elastic response stays about the same, but fracture strength depends a lot on microscopic flaws, and plastic deformation gets weird in small spaces.

Elasticity and Strength

Elastic properties don’t really change from big to small. When we test tiny samples, their elastic modulus lines up with what we see in bigger pieces.

Crystal structure is the big factor here. If we know the texture, we can predict elastic response pretty well. The same anisotropic elastic constants work at both scales.

But strength? That’s a different story. Tiny samples usually show way higher strength than bulk material. That’s because there are fewer flaws in a small chunk.

Brittle materials get their strength from flaw distribution. A tiny bit might dodge the big cracks that would ruin a larger piece. MEMS devices show this clearly—fracture strength can swing wildly based on how they’re made.

Compare a nanowire to a bulk bar, and you’ll see the size effect. The little one can be ten times stronger.

Fracture and Failure Mechanisms

Fracture toughness—the basic resistance to cracks—stays steady no matter the size. But fracture strength? That can jump all over the place. Small samples break at higher stresses because they’re less likely to have a killer flaw.

We usually see three main ways things fail:

- Brittle fracture led by surface flaws.

- Fatigue failure from repeated loading.

- Environmental damage like oxidation or corrosion.

MEMS devices run into special problems. Their high surface-to-volume ratio makes them super sensitive to scratches or thin oxide layers. Sometimes, a tiny scratch decides where the whole thing fails.

Testing at these scales isn’t easy. We need special gear to grip and pull on tiny samples without wrecking them.

Plasticity and Creep

Plastic deformation gets weird at small scales. Confined spaces change how dislocations move. This leads to size-dependent strength you just don’t see in bigger pieces.

Dislocation behaviour flips. In tiny samples, dislocations can’t multiply or move like they do in bulk. They often get stuck at surfaces or boundaries.

Smaller samples tend to be stronger. That “smaller is stronger” effect pops up in metals, ceramics, and even polymers. The tight space blocks normal dislocation movement.

Creep—the slow, time-based deformation—also changes. Tiny samples might resist creep better, since surface effects start to matter more than bulk diffusion.

We use special tools like nanoindentation and microscale tensile testers to measure all this.

Micro Mechanics in Composites and Advanced Materials

Composites don’t behave like single materials because their tiny parts interact in tricky ways. The bonds between different materials decide how well the composite holds up under pressure.

Behaviour of Composite Phases

Each part of a composite has a job. The matrix glues everything together and spreads out force. The reinforcement—like fibres or particles—takes most of the load.

When you push or pull on a composite, the force moves from the matrix to the reinforcement at their contact points. That transfer happens at the micro scale, but it controls the whole material’s performance.

Different phases can expand or shrink at different rates when things heat up or cool down. This builds up stress inside, even if there’s no outside load. If we understand those stresses, we can predict how and when composites might fail.

Shape and size of the reinforcement matter a lot. Long fibres act differently than short ones. Round particles aren’t anything like flat ones.

The amount of each phase changes the big picture, too. More reinforcement usually means stronger material—but only up to a point.

Interface Effects and Bonding

The spot where different phases meet often turns out to be the weakest link in a composite. If the bonding isn’t good, you’ll see early failure and poor performance.

Chemical bonding forms the strongest connections. The matrix and reinforcement actually create chemical links right at their surfaces.

Physical bonding, on the other hand, relies more on friction and mechanical interlocking. It’s not as strong, but sometimes it’s all you’ve got.

You can improve bonding with surface treatments. These treatments change the surface chemistry of fibres or particles before they go into the matrix.

Cracks usually get started at the interface between phases when composites break down. After that, the crack moves through the weaker matrix material.

Modern composites use special coupling agents to strengthen the bond. These molecules grab onto the reinforcement with one end and stick to the matrix with the other.

Over time, temperature and moisture can eat away at interfaces. That’s a big reason why some composites lose their strength in harsh environments.

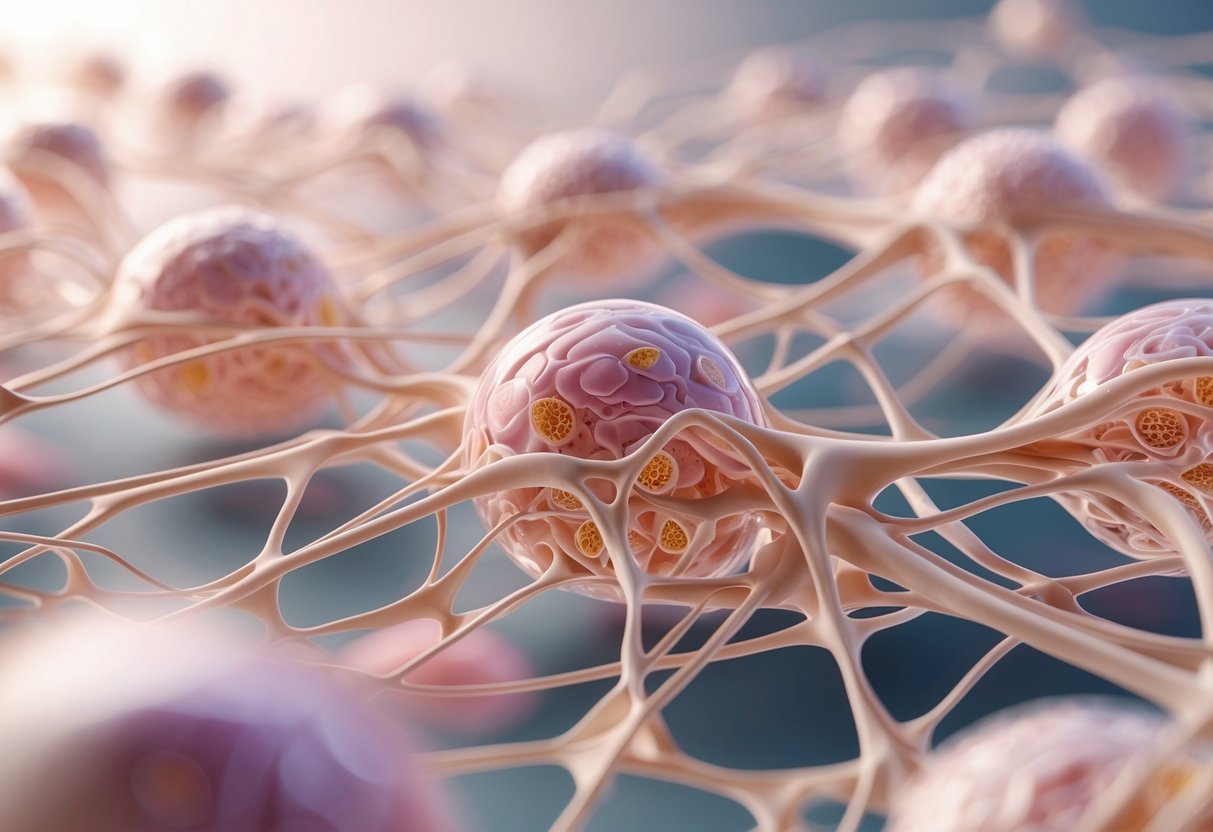

Micro Mechanics of Biological Tissues

Biological tissues throw some unique mechanical challenges at us—stuff you just don’t see with regular engineering materials. The way these tissues are put together on a tiny scale shapes how they work in our bodies.

Unique Challenges of Soft Matter

Biological tissues don’t act like metals or plastics at all. They stretch, compress, and morph in ways that are tough to predict.

Key differences include:

- Non-linear responses – tissues ignore simple stress-strain rules

- Time-dependent behaviour – fast or slow loading changes the response

- Living material properties – they can heal, adapt, and even grow

Soft tissues like skin and muscle are full of water and complicated protein structures. Honestly, they’re more like gels than solid stuff.

The real challenge comes from all the different length scales working together. What goes on at the cellular level affects the whole tissue, making it tricky to predict how it’ll react to forces.

Microstructural Impact on Tissue Function

Tiny structures inside tissues control their mechanical properties. Collagen fibres, cells, and other bits all team up to create how the tissue behaves.

Critical microstructural elements:

- Fibre orientation – sets the direction of strength

- Cell arrangement – changes stiffness and response

- Protein networks – handle elasticity and recovery

Different tissues evolved their own microstructures for specific jobs. Bone packs in hard minerals for strength, while cartilage uses a gel-like matrix to cushion joints.

If we get how these micro features work, we can predict tissue behaviour better. That knowledge helps us design treatments, artificial materials, and medical devices that fit with the body’s natural mechanics.

Modelling and Analytical Methods in Micro Mechanics

Micro mechanics leans heavily on mathematical models to figure out how tiny features shape overall behaviour. These methods go from treating materials as smooth blobs to simulating each particle on a computer.

Continuum Approaches

Continuum mechanics sits at the heart of most micro mechanical analysis. We treat materials as continuous, not as a pile of atoms or molecules.

This works well if properties stay pretty uniform across small areas. Classical mechanics equations relate stress and strain at different scales.

Key advantages include:

- Solid mathematical foundation

- Easy to combine with engineering tools

- Efficient for big structures

Continuum models do a great job capturing bulk material behaviour. They tell us how cracks grow, how composites bend, and how metals deform under load.

Problems pop up when features get really tiny. At the nanoscale, continuum assumptions start to crumble, and we need more detailed methods.

Engineers use these models all the time in finite element software. The math behind beams, plates, and shells all comes from continuum mechanics.

Homogenisation and Dehomogenisation

Homogenisation lets us turn complex micro structures into simple material properties. We take details about fibres, particles, or grains and boil them down to averages.

We start with a representative volume element (RVE). This small chunk has all the important micro features. We load it up and see how it reacts.

The homogenisation process:

- Define the RVE geometry

- Set up boundary conditions

- Calculate effective properties

- Check results against experiments

Dehomogenisation flips things around. We start with bulk properties and try to predict local stresses and strains inside the microstructure.

These techniques are crucial in composite design. Aircraft makers use them to fine-tune carbon fibre layouts. Wind turbine designers predict how long glass fibre blades will last.

Choosing the right RVE size is tricky. Too small, you miss stuff. Too big, and your computer might just give up.

Numerical and Computational Techniques

Modern micro mechanics leans a lot on computer simulation. Finite element methods are everywhere, but other approaches are catching up.

Popular computational approaches:

- Finite element analysis – slices materials into tiny elements

- Molecular dynamics – follows atom-by-atom movements

- Monte Carlo methods – uses random sampling for stats

- Boundary element methods – focuses on surfaces

Finite element models can handle wild geometries and loading. We build detailed 3D models of fibre bundles, particle clusters, or crystal patterns.

Molecular dynamics tracks thousands of atoms, catching things continuum methods just miss. They’re especially handy for studying interfaces between different materials.

Computational challenges include:

- Big memory demands

- Long calculation times

- Needing specialised software

- Tough to validate results

Modern graphics cards really speed things up. What used to take weeks now wraps up in hours. That kind of speed opens up new doors for testing materials virtually.

Virtual prototyping is the dream. We design new materials on computers before ever making a sample. It saves time, cuts costs, and lets us try more ideas.

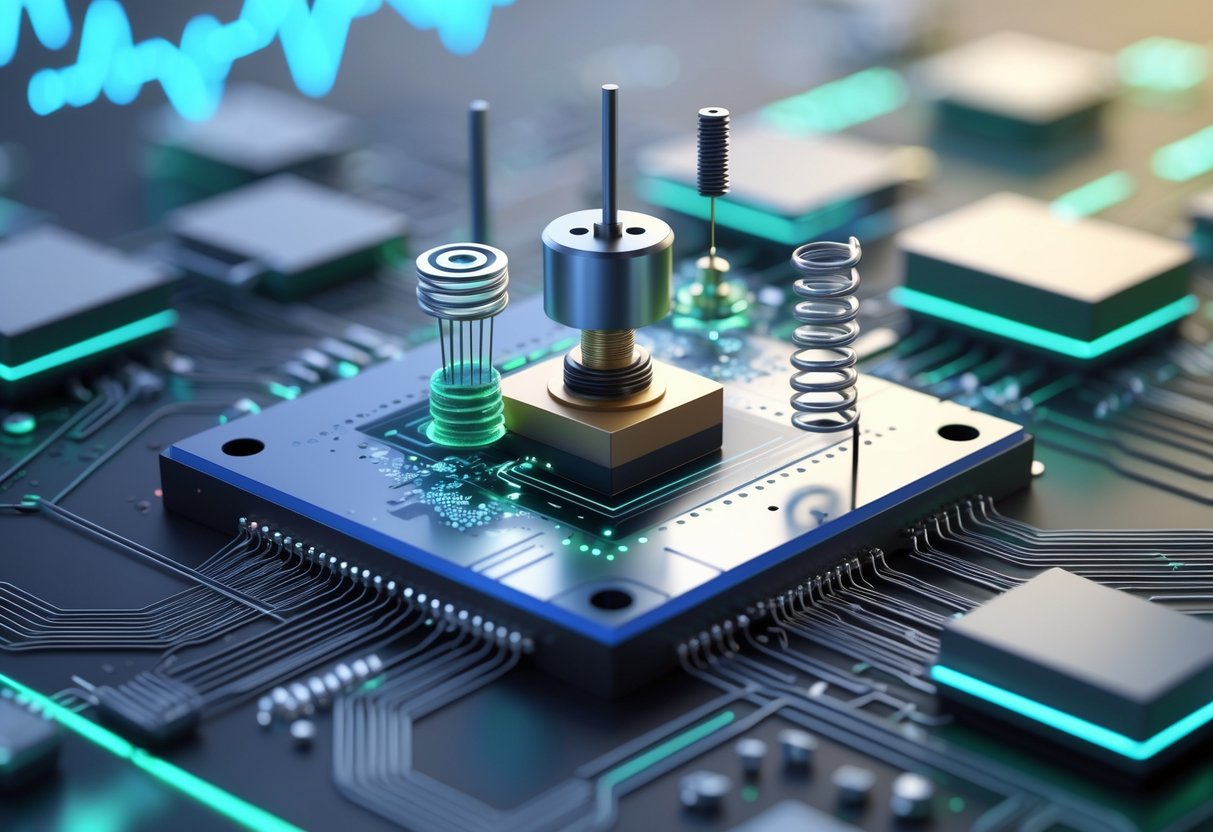

Role of Micro Mechanics in Sensors and MEMS

MEMS devices depend on precise mechanical principles to pick up changes and respond to signals. These tiny systems mix moving parts with electronics to make sensors for everything from motion to pressure.

Design Principles for MEMS Devices

Good MEMS design starts with knowing how forces work at the microscale. Materials act differently when they’re just a few micrometres thick.

Key mechanical elements include:

- Cantilevers that bend when forces hit

- Membranes that flex under pressure

- Springs that control movement

- Masses for inertial sensing

Material choice matters a lot. Silicon is a favourite because it’s strong and behaves predictably, even when structures get tiny.

Scaling effects really shake things up. Surface forces start to matter more than volume forces. Friction and sticking become real headaches—problems you just don’t see in big machines.

We design for specific responses. An accelerometer needs a mass that shifts with acceleration. A pressure sensor wants a membrane that bends when pressure changes.

Microscale Mechanisms in Sensors

Sensors turn physical changes into electrical signals through mechanical movement. The mechanical bits pick up the change, while electronics measure what happened.

Common sensing mechanisms include:

| Sensor Type | Mechanical Action | What It Measures |

|---|---|---|

| Accelerometer | Mass displacement | Motion and tilt |

| Gyroscope | Vibrating element | Rotation |

| Pressure sensor | Membrane deflection | Air or liquid pressure |

| Microphone | Diaphragm movement | Sound waves |

Capacitive sensing works by changing the distance between surfaces. When something moves, capacitance shifts, and we measure that to track movement.

Piezoelectric mechanisms create electrical signals when materials deform. Some crystals spit out voltage when you squeeze or bend them. That makes sensors more sensitive.

Resonant sensors shift their vibration frequency when conditions change. A tiny beam vibrates at different speeds if you add mass or change the temperature. We measure those frequency changes to sense what’s going on.

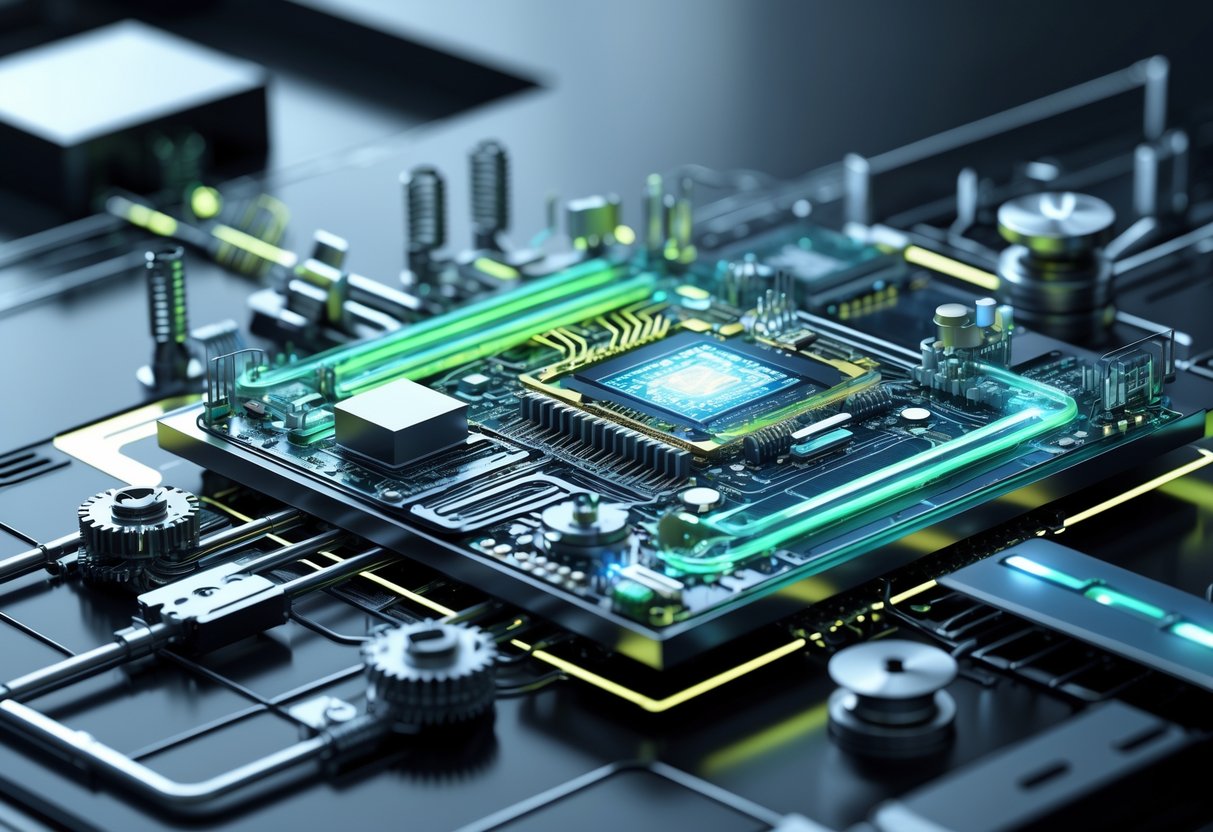

Micro Mechanics in Electronics and Nanotechnology

Micro mechanics fuels the creation of incredibly small electronic parts and sensors. It lets engineers build tiny gadgets for smartphones, medical implants, and spacecraft—while keeping everything precise.

Impact on Electronics Miniaturisation

MEMS Technology Revolution

Micro-electromechanical systems (MEMS) stand out as a major win for micromechanics in electronics. These devices put mechanical and electrical parts together on a single chip.

Common MEMS applications include:

- Accelerometers in phones for screen rotation

- Gyroscopes in gaming controllers

- Pressure sensors in car tyres

- Microphones for hearing aids

Precision at this scale takes a deep understanding of how materials act microscopically. Engineers use micromechanics to predict how silicon bends, vibrates, or responds to signals.

Semiconductor Manufacturing

Modern chips depend on micromechanics for production. Etching and deposition create features smaller than a human hair.

These processes have to deal with:

- Thermal expansion at different temps

- Stress between layers

- Mechanical stability during handling

Smart Materials and Actuators

Shape Memory Alloys

Micromechanics helps design smart materials that change shape when heated or electrified. These materials drive tiny actuators in medical and precision devices.

Applications include:

- Stents that expand in blood vessels

- Micro-grippers for delicate parts

- Thermal switches that turn on automatically

Piezoelectric Systems

These materials make electricity when squeezed or vibrate when powered. Micromechanics predicts how they’ll act at small scales.

Engineers use them for:

- Hospital ultrasound imaging

- Precision stages in microscopes

- Harvesting energy from vibrations

At micro scales, these materials behave differently than in bulk, so micromechanics is key for reliable designs.

Investigating Materials at the Atomic Scale

At the atomic level, we get to watch atoms interact and move when materials take on stress. This kind of study uses molecular dynamics simulations to predict material behaviour before anything’s built.

Atomic Interactions and Mechanical Behaviour

When we dig into materials at this scale, we look at how atoms bond and react to forces. These tiny interactions decide if something ends up strong or weak.

Atoms at the surface act differently than those inside. Surface atoms have fewer neighbours and feel less stable, which creates surface stress.

Key atomic behaviours include:

- Atoms shifting to new spots under stress

- Chemical bonds breaking and reforming

- Crystal structures morphing

- Atoms diffusing to lower energy

The surface area to volume ratio matters a lot in small materials. More atoms sit on the surface, which changes how the whole material behaves.

When materials shrink below a few nanometres, normal plastic deformation might just stop working. Instead, you might see phase transformations—where the whole crystal structure flips.

Small-scale materials often end up way stronger than their bigger counterparts. That’s because there aren’t many places for defects to get started.

Simulation and Predictive Modelling

Molecular dynamics simulations let us watch atoms move during mechanical tests. These computer models track every atom and calculate all the forces.

Simulation advantages:

- Study materials too tiny for real tests

- Control every condition

- Watch atomic motion directly

- Try risky or expensive scenarios safely

But simulations have their limits. They usually run at strain rates way faster than real life, just to finish in a reasonable time.

The accuracy depends on the math models for atomic interactions. Sometimes, these models miss important physics.

Modern simulations can now handle millions of atoms at once. We can see how cracks start, how materials fail, and how new structures form under stress.

These predictions help us design better materials before we ever make them. We can test different mixes and structures virtually first.

Applications and Industry Impact of Micro Mechanics

Micromechanics sparks innovation in some of the world’s most important industries. By letting us control material behavior on a microscopic level, it changes how we design and build everything from lightweight airplane parts to medical devices that save lives.

This field keeps pushing the limits of high-performance materials.

Aerospace and Automotive Advancements

Micromechanics is really shaking up transportation with new composite materials. Carbon nanotubes and fiber-reinforced composites cut aircraft weight by as much as 30%, yet still keep things strong.

Aircraft engineers use micromechanics to create parts that survive extreme stresses. They analyze fibers at the microscopic scale to design better wing structures.

Automakers take advantage too. Lightweight panels and engine parts boost fuel efficiency and help lower emissions. Nanocomposites in car bodies offer impressive crash protection but weigh a lot less than steel.

Surface coatings from micromechanics research fight off corrosion and wear. Engine parts last longer and handle stress better, which cuts down on maintenance headaches.

Biomedical Devices and Innovations

Medical devices absolutely depend on micromechanics to work with human tissue. Stents and prosthetics need to flex and bend without breaking down inside the body.

We’ve developed biomaterials that match bone stiffness almost perfectly. Now, hip replacements last much longer, thanks to materials science giving us better mechanical matches.

Drug delivery systems use tiny mechanical parts to work their magic. Microsensors track blood pressure and glucose levels with crazy precision. These gadgets have to survive for years in tough environments inside the body.

Nanoindentation helps us test how materials interact with living cells. This kind of research leads to surgical tools and implants that do less damage to tissues.

Sustainable Materials Engineering

Environmental worries push micromechanics toward greener answers. We’re making biodegradable composites that stay strong but break down safely after use.

Microscopic engineering gives recycled materials new life. We can turn plastic waste into high-performance building materials by tweaking its molecular structure. This keeps trash out of landfills and creates something useful.

Solar panels and wind turbines get a boost from weather-resistant materials. Micromechanics lets us make surfaces that self-clean and stay efficient for decades.

2D materials like graphene are incredibly strong but use fewer resources. They offer top-notch performance in electronics and structures, all while keeping the environmental impact low.

Challenges and Future Trends in Micro Mechanics

Micro mechanics faces some tough technical challenges that hold back precision and large-scale use. But with tools like high-res microscopes and AI-driven systems, we’re seeing new doors open for industry breakthroughs.

Current Limitations

Scale effects create headaches in micro mechanical systems. Traditional manufacturing just can’t make parts smaller than 100 micrometers with good accuracy.

Material behavior flips at micro scales. Surface forces start to matter more than volume forces. Predicting how tiny parts will work gets far trickier than with big components.

Micro machining tools wear out fast. The tiny contact areas and need for precision mean cutting tools break down quickly. This drives up costs and leads to inconsistent results.

Measuring micro parts is tough. Standard tools can’t check if these tiny pieces meet specs. We need specialized, pricey equipment for that.

Managing heat at micro scales is a pain. Little parts heat up and cool off fast during manufacturing, which can cause warping or cracking.

Vibration control demands real precision. Even small shakes from nearby machines can ruin micro manufacturing. Factories need expensive systems just to keep things stable.

Emerging Tools and Technologies

High-res microscopy lets engineers watch micro manufacturing in real time now. Scanning probe microscopy can spot features as tiny as atoms, so problems get caught before they waste a whole batch.

Nanotechnology is changing the game for micro mechanical systems. Carbon nanotubes and graphene bring strength-to-weight ratios that old-school materials just can’t match.

AI-powered controls learn from manufacturing data. These systems tweak cutting speeds and tool paths on the fly, cutting waste and making production more reliable.

In-situ testing checks parts as they’re being made. Combining electron microscopy with mechanical tests shows exactly how materials behave during the process.

New coatings make tools last much longer. Diamond-like carbon and other advanced surfaces keep cutting tools sharp, saving money and boosting precision.

Hybrid machines blend several processes in one. Lasers, mechanical cutters, and chemical etching all work together to make complex micro parts.

Opportunities for Innovation

Medical device manufacturing has tons of room for micro mechanics to grow. Miniaturized surgical tools and implantable sensors need super-precise production.

MEMS device production keeps expanding into fresh markets. Smart sensors for cars, phones, and factories all use micro mechanical parts. These markets are growing fast.

Quantum tech needs micro mechanical systems with jaw-dropping precision. Quantum computers and sensors rely on positioning mechanisms that work at the nanometer scale.

Aerospace companies want lighter, stronger micro components. Micro actuators and sensors can cut aircraft weight and improve monitoring systems.

Consumer electronics keep shrinking and adding features. Micro mechanics makes folding phones, advanced cameras, and wearables possible—things that sounded like sci-fi not long ago.

Biotech is getting in on the action with lab-on-chip devices. These run complex medical tests with just a drop of blood.

Environmental monitoring uses networks of micro sensors. Thousands of tiny devices can track air, water, and climate changes over huge areas.

Frequently Asked Questions

Micro-mechanics tackles some pretty tough challenges in technology, materials science, and automotive diagnostics. Here are a few common questions about how micro-scale engineering shapes today’s innovations.

What are the key applications of micro-mechanical engineering in today’s technology?

Micro-mechanical engineering powers semiconductor manufacturing, where precision parts let us make chips at nanometer scales. You’ll find these parts in wafer fabrication tools that build processors and memory.

Medical devices use micro-mechanics for surgical instruments and implants. You’ll see micro-machined parts in pacemakers, hearing aids, and minimally invasive tools.

The automotive world relies on micro-mechanical sensors for airbags, engine management, and stability control. These tiny bits detect pressure, acceleration, and temperature with impressive accuracy.

Consumer electronics wouldn’t be the same without micro-mechanical parts in cameras, hard drives, and touchscreens. Each one has to work reliably, even at microscopic sizes.

How does micro-mechanics enhance the performance of composite materials?

Micro-mechanics helps us figure out how fibers and matrix materials interact inside composites. With this info, engineers can predict how materials will behave before building expensive prototypes.

We can use micro-mechanical models to optimize fiber orientation and spacing. These calculations help us find the best setup for specific loads in aerospace and automotive uses.

Failure analysis gets a lot more precise with micro-mechanics. Engineers spot weak spots at the microscopic level and redesign materials to avoid big failures.

Manufacturers improve quality control by understanding micro-scale interactions. They catch defects early and tweak processes to keep properties consistent.

What role does micro-mechanics play in the development of precise measurement instruments?

Micro-mechanical sensors make super-accurate measurements possible in industry. These devices can detect forces, pressures, and movements measured in micrometers or smaller.

Calibration standards depend on micro-mechanics for reference measurements. National labs use micro-engineered artifacts to keep measurements consistent worldwide.

Environmental monitoring gear uses micro-mechanical accelerometers and pressure sensors. Weather stations, seismic monitors, and pollution detectors all rely on these instruments.

Manufacturers use micro-mechanical gauges for dimensional checks. These tools measure tolerances that traditional instruments just can’t catch.

Could you explain the impact of micromechanics research on modern material science?

Micromechanics research shows how atomic-scale properties affect material behavior overall. This knowledge leads to stronger, lighter materials for aerospace and construction.

We can now design materials with specific properties by tweaking their microstructure. Engineers make composites with tailored stiffness, thermal expansion, or electrical conductivity.

Additive manufacturing benefits from micromechanics insights about layer bonding. 3D printing produces better parts when manufacturers understand what’s happening at the microscale.

Biomaterials research uses micromechanics to match implants with human tissue. Hip and dental implants last longer when their properties fit natural bone.

What are the cutting-edge innovations in micro-mechanical engineering currently being explored?

Nano-scale manufacturing is pushing micro-mechanics into wild new territory. Researchers are coming up with ways to build parts smaller than bacteria.

Smart materials use micro-mechanical actuators that change shape when triggered. These make self-healing composites and adaptive structures for aerospace.

Micro-robotics blends mechanics and electronics to create tiny autonomous machines. These could change how we deliver drugs or repair cells.

Quantum sensors use micro-mechanical resonators to spot gravitational waves and magnetic fields with crazy sensitivity. This tech could open up new frontiers in physics.

How does the micro mechanic app aid in diagnosing vehicle issues?

You connect the Micro Mechanic app to your car’s diagnostic port with a small Bluetooth device. It reads error codes and turns them into plain English explanations.

While you drive, real-time monitoring shows engine performance and fuel efficiency. You can also see emission levels as they change.

The app lets you know about potential problems before they turn into something expensive. Honestly, that’s a relief—who wants a surprise repair bill?

You can track repair costs and keep an eye on maintenance schedules. Comparing results over time makes it easier to spot issues before they get out of hand.

Troubleshooting guides walk you through common problems. The app even suggests if you need to fix something right away or if it can wait, which saves you from unnecessary trips to the garage.