Bracket Software Analysis: Advanced Methods for Engineering Success

Updated On: November 13, 2025 by Aaron Connolly

Understanding Bracket Software Analysis

Bracket software analysis combines engineering calculation tools with design optimisation to test how mechanical brackets perform under real-world conditions.

We use programs like ANSYS and SolidWorks to predict stress, deformation, and failure points before building any physical prototypes.

Definition and Importance

Bracket software analysis lets us test how brackets behave under different forces and conditions—without building and breaking dozens of real brackets.

We can run virtual tests that highlight exactly where stress piles up and how much the bracket will bend or twist.

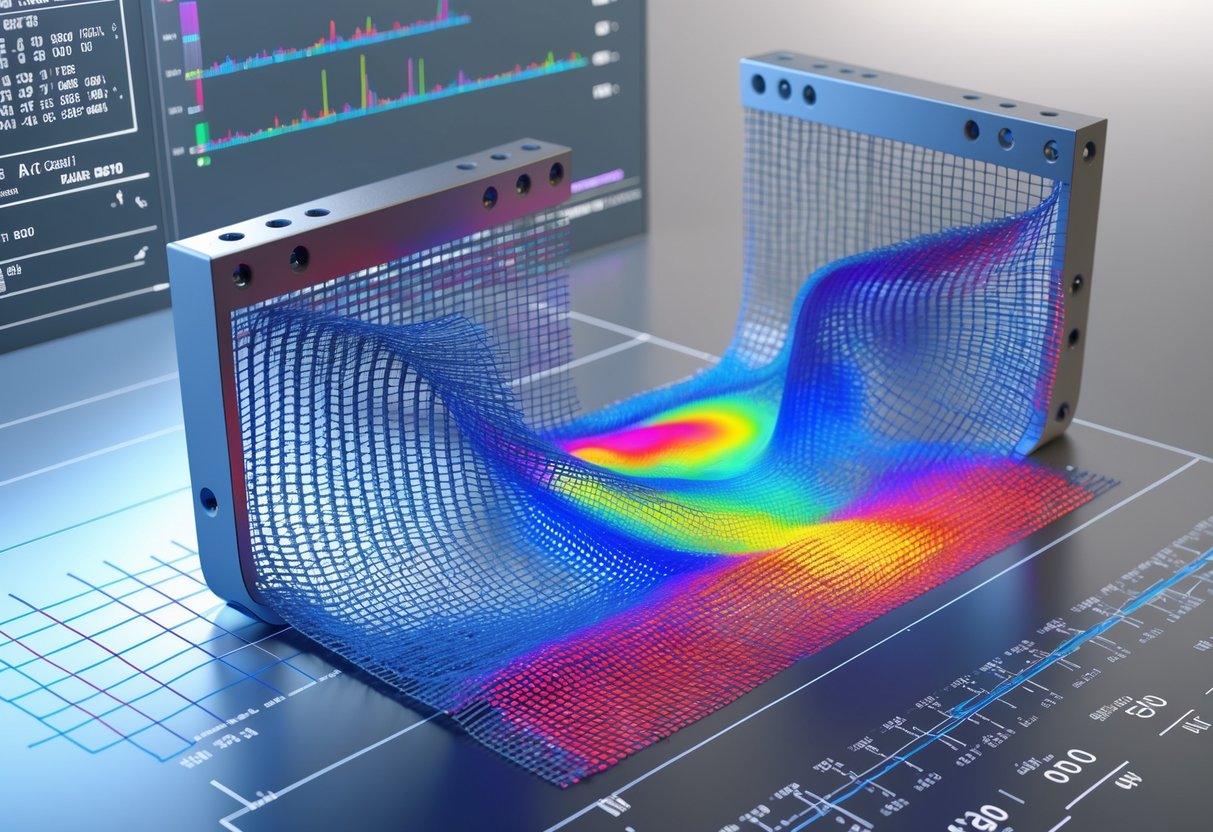

The analysis usually involves finite element analysis (FEA). FEA breaks down complex bracket shapes into thousands of tiny pieces called elements.

We calculate each element separately, then combine the results to get the full picture.

Why does this matter for engineers?

- Cost savings: Virtual tests are way cheaper than making physical prototypes

- Speed: We can run 50 design variations in the time it takes to machine a single bracket

- Safety: Finds failure points before the bracket ever sees real-world use

Modern bracket analysis software can predict failure with about 95% accuracy.

That kind of reliability means engineers can confidently pick materials, dimensions, and mounting points based on computer results alone.

Key Applications in Engineering

Bracket software analysis pops up in all sorts of industries where failure isn’t an option.

Aerospace brackets supporting engine mounts go through thousands of stress cycles. Engineers absolutely rely on precise analysis to avoid disaster.

Automotive applications include suspension mounts, engine brackets, and chassis connections.

Software analysis helps engineers strike that tricky balance between reducing weight and keeping enough strength. A typical car bracket analysis might run through 15 different load cases, including things like emergency braking and crash scenarios.

Manufacturing equipment depends on bracket analysis for conveyor systems, robotic arms, and assembly line parts.

These brackets often support moving loads that change throughout the operation.

Tournament bracket software takes a different approach. Systems like Bracket Ninja use algorithms to analyse team performance and set up fair matchups.

This helps avoid situations where the strongest teams knock each other out right away.

Common Types of Bracket Analysis

Static analysis checks how brackets react to constant, unchanging loads.

We apply forces and look at the resulting stress patterns and deformation. Most bracket designs start with static analysis to get a baseline.

Modal analysis finds natural vibration frequencies in bracket structures.

We want to avoid resonance—when operating frequencies match the bracket’s natural frequency—because that can lead to destructive vibrations.

Fatigue analysis predicts how many loading cycles a bracket can survive before cracking. This is crucial for brackets that get loaded over and over, like vehicle suspension mounts or machinery supports.

| Analysis Type | Best For | Typical Duration | Key Output |

|---|---|---|---|

| Static | Fixed loads | 30-60 minutes | Stress distribution |

| Modal | Vibrating systems | 1-2 hours | Natural frequencies |

| Fatigue | Repeated loading | 2-4 hours | Cycle life prediction |

Topology optimisation strips away unnecessary material while keeping the bracket strong enough.

The software redesigns the bracket shape, sometimes producing wild, organic-looking structures that outperform traditional designs.

Core Principles of Structural Analysis for Brackets

Understanding how loads move through bracket structures and picking the right materials forms the backbone of solid bracket design.

These principles decide whether your bracket will handle real-world forces or fail when it matters most.

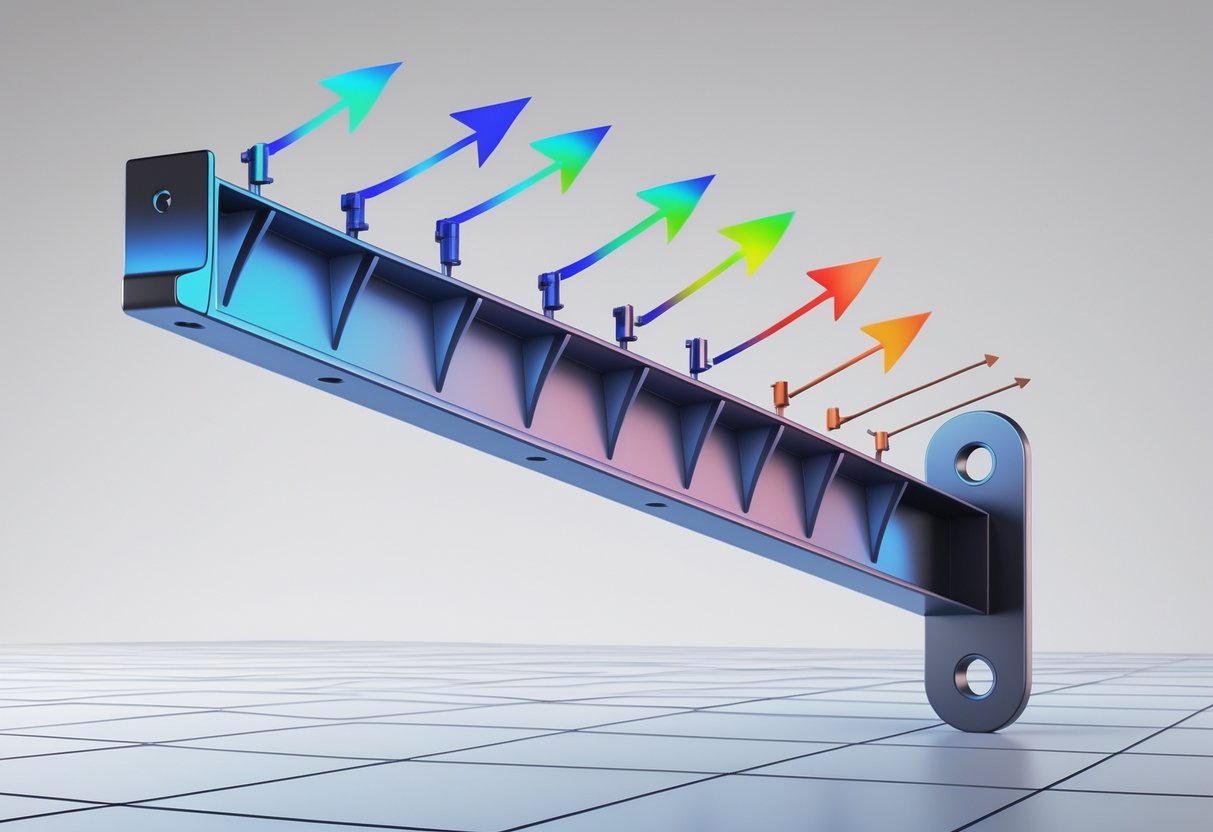

Load Distribution Mechanisms

Load distribution describes how forces travel through a bracket from where you apply them to where the bracket is supported.

Distributed load scenarios are super common in bracket applications.

When we put force on a bracket, the load spreads through the material along stress paths that follow the bracket’s geometry.

Sharp corners and sudden changes in thickness create stress concentrations.

Loads don’t just go straight down. Forces flow around holes, bend at corners, and pile up at support points.

Critical load paths include:

- Direct compression through vertical members

- Bending moments at connection points

- Shear forces along horizontal surfaces

- Concentrated stresses around bolt holes

We need to design brackets so even the weakest spot can handle the maximum expected load.

That means spotting where stress concentrates and either beefing up those areas or spreading the load out.

Material Selection Considerations

Material choice changes how a bracket handles stress and spreads loads.

Different materials have different strengths, and that affects load distribution.

Steel gives you high strength and predictable behaviour under load. It handles both tension and compression well.

Aluminium offers a good strength-to-weight ratio, but you’ll need thicker sections to match steel’s strength.

Key material factors for brackets:

| Property | Steel | Aluminium | Importance |

|---|---|---|---|

| Yield Strength | High | Moderate | Prevents permanent deformation |

| Elastic Modulus | High | Lower | Controls deflection |

| Fatigue Resistance | Good | Variable | Handles repeated loading |

We have to consider things like operating temperature, corrosion resistance, and how easy the material is to manufacture.

The elastic modulus affects how loads move through the structure.

Stiffer materials concentrate loads more sharply. Flexible ones spread loads out but might deflect too much.

Finite Element Analysis in Bracket Design

Finite element analysis (FEA) chops up bracket structures into thousands of tiny elements to predict their behaviour under real-world forces.

Modern tools like ANSYS and SolidWorks use different meshing and solver tech to deliver stress predictions you can actually trust.

Overview of FEA Techniques

FEA breaks complex bracket shapes into manageable pieces called elements.

Each element connects to its neighbours through nodes, forming a mathematical network for the whole structure.

Static analysis looks at how brackets handle constant loads.

We apply forces like motor torque or mounting loads and see where stress builds up. The software spits out deformation, stress distribution, and safety factors across the bracket.

Dynamic analysis dives into vibration behaviour.

Motors and other moving parts create oscillating forces that can wreck brackets over time. Modal analysis finds the natural frequencies where resonance could become a problem.

Key FEA outputs include:

- Von Mises stress distribution

- Total deformation values

- Safety factor calculations

- Natural frequency modes

Topology optimisation is a more advanced FEA trick.

It removes material from low-stress areas while keeping the bracket strong. Studies show this can cut bracket mass by up to 76% without hurting performance.

Mesh Generation and Refinement

Mesh quality really matters for FEA accuracy.

Coarse meshes run fast but miss stress hotspots. Fine meshes pick up more detail but eat up computing power.

Critical meshing considerations:

- Element size: Go smaller near bolt holes and sharp corners

- Element type: Use tetrahedral for weird shapes, hexahedral for regular ones

- Aspect ratio: Don’t let elements get too stretched or squashed

We usually start with automatic meshing, then zoom in on problem areas.

Stress concentrations around mounting points need finer elements to catch those peak values.

A convergence study helps confirm when the mesh is dense enough.

Common mesh errors include:

- Distorted elements with bad geometry

- Not enough refinement at key locations

- Over-meshing in low-stress regions

Quality metrics help spot troublesome elements.

Skewness should stay under 0.8, and orthogonal quality should be above 0.2 for good results.

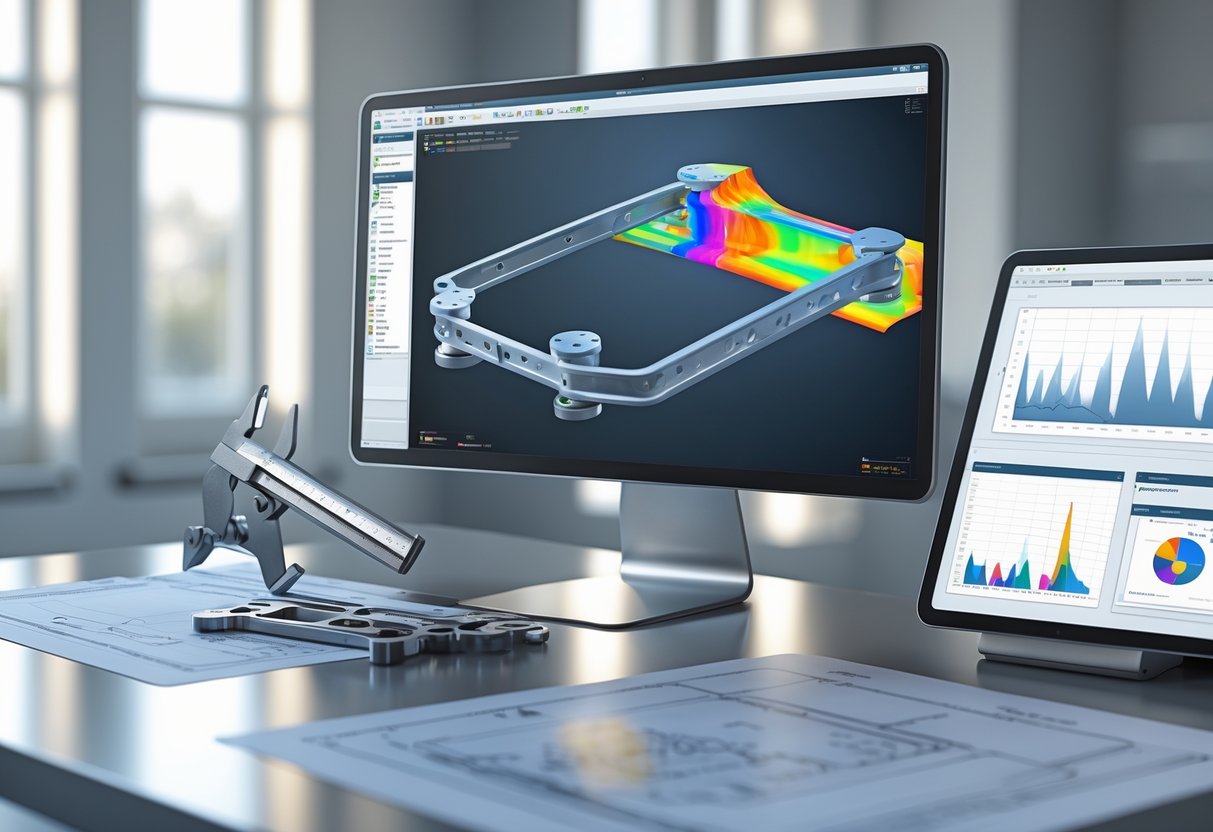

Comparative Study: SolidWorks vs ANSYS

Both SolidWorks and ANSYS handle bracket analysis well, but they serve different needs.

| Feature | SolidWorks Simulation | ANSYS Workbench |

|---|---|---|

| Learning curve | Moderate | Steep |

| Meshing control | Basic automatic | Advanced manual |

| Solver technology | Direct sparse | Multiple options |

| Topology optimisation | Limited | Full featured |

| Cost | Moderate | High |

SolidWorks Simulation shines for basic bracket analysis.

Its built-in CAD makes design tweaks quick. The automatic meshing is fine for simple shapes, and results display right inside the familiar interface.

ANSYS Workbench digs deeper. You get advanced meshing for complex brackets, more solver options, and full-featured topology optimisation.

If you just need to validate a basic bracket, SolidWorks is fast and accurate enough.

For tricky brackets with lots of load cases, dynamic effects, or serious optimisation, ANSYS is the better bet.

Quick tip: Start with SolidWorks for quick checks, then switch to ANSYS if you need more detail and control.

Stress and Strain Evaluation in Bracket Analysis

When we run bracket analysis software, we mainly want to see how much stress builds up and how much the bracket deforms under load.

Tools like ANSYS, SimScale, and CATIA help us map these values across the whole bracket structure.

Stress Mapping and Visualisation

Von Mises stress is the go-to value in bracket analysis.

It shows us where the bracket is closest to failing.

Most software shows stress results as colour maps. Red highlights high stress zones, while blue means low stress.

The highest stress almost always shows up near:

- Load application points where forces enter the bracket

- Sharp corners and sudden geometry changes

- Connection holes for bolts or fasteners

We can tweak the stress scale to make problem areas pop out.

A lot of engineers use a scaling factor between 10 and 50 to make even small stress concentrations obvious.

Heads up: Always double-check that your max stress stays below the material’s yield strength, with a solid safety factor.

The software calculates stress distribution across thousands of mesh elements, giving us a detailed look at how forces travel through the bracket.

Strain Distribution Assessment

Strain tells us how much the bracket stretches or squashes under load.

We usually look at elastic strain to be sure the bracket bounces back to shape after loading.

Displacement magnitude shows how much each point moves.

Fixed supports won’t move at all, while free ends show the most displacement.

Common strain patterns include:

- Bending strain along the bracket’s length

- Tensile strain where the material stretches

- Compressive strain at bent regions

Software lets us scale up displacement visuals because real deformations are often tiny.

A scaling factor of 50 or even 100 helps us spot the deformed shape.

We can also check strain energy to see how much energy the bracket absorbs during loading.

That helps us tweak the design for better performance while using less material.

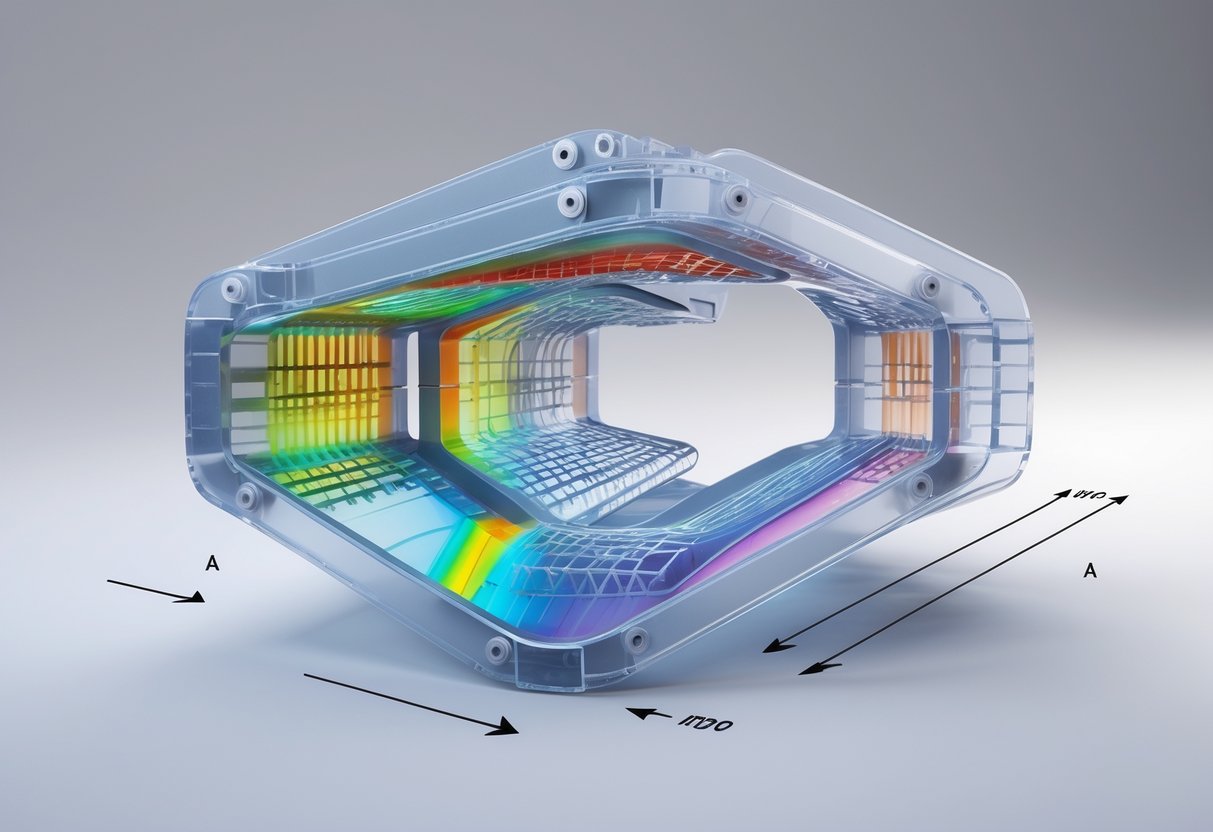

Deformation Assessment and Modelling

Measuring deformation helps us predict how brackets bend and change shape under different loads.

Software tools make it easy to test designs virtually before we ever build a real part.

Methods for Deformation Measurement

Modern bracket analysis software uses a few main techniques to measure deformation.

Finite element analysis (FEM) splits the bracket into small elements and calculates how each one moves when we apply forces.

Most engineering software automates deformation tracking.

ANSYS Workbench even has step-by-step tutorials for measuring bracket displacement.

Results show up in colour-coded maps, so you can spot deformation patterns at a glance.

We can scale up small deformations to make them easier to see.

A lot of programs let you multiply displacement by 50 or 100 times, which helps pinpoint trouble spots that might otherwise be invisible.

SimScale gives you cloud-based deformation analysis with built-in material libraries.

The platform includes steel properties and templates for setting up boundary conditions.

You can apply forces up to 30,000 Newtons and get instant results.

Software usually measures three key values:

- Total displacement in millimetres

- Von Mises stress at deformation points

- Maximum deflection under load

Significance in Bracket Integrity

Deformation plays a big role in how long brackets actually last. Even a tiny bend can turn into a crack if you ignore it long enough.

When we look at deformation patterns, we get clues about how to make parts tougher. Weak points usually show up where brackets bolt onto other stuff.

These critical stress zones pop up fast in simulations. We jump on these trouble spots first when we tweak the design.

Topology optimisation takes all that deformation data and trims away material we don’t need. Some studies say we can drop bracket weight by 40% and still make them stiffer. That’s a win for both cost and reliability.

Software lets us compare bracket shapes fast. We can run identical loads on C-brackets, L-brackets, or some weird custom geometry. The results tell us which shape survives best for each job.

If we check deformation properly, we dodge expensive failures. Breaking virtual models costs way less than smashing real prototypes.

Software Solutions for Bracket Analysis

Engineering teams now lean on specialised software to check bracket performance under loads and various conditions. These platforms mix finite element analysis with smart modelling, so we can save on materials and still get tough designs.

Abaqus for Aerospace Applications

Abaqus really leads the pack for aerospace bracket analysis. Teams use it to simulate the wild stress that aircraft parts face in the air.

The software shines at non-linear finite element analysis. It models what happens when materials get pushed to the edge or bend a lot.

Key capabilities include:

- Complex material modelling (composites, metals, ceramics)

- Dynamic loading simulations

- Fatigue life predictions

- Temperature-dependent analysis

Aerospace engineers love Abaqus for its ESO (Evolutionary Structural Optimisation) tools. The software chops off material from low-stress spots but keeps the bracket strong.

Big names like Boeing and Airbus use Abaqus to check bracket designs before they build anything. It can predict how and when parts might fail—sometimes years before it would happen in real life.

Cost is still a big deal. Abaqus licenses start at around £15,000 each per year. Still, the savings show up in fewer tests and better safety margins.

AStrutTie and Strut-and-Tie Modelling

AStrutTie focuses on concrete bracket analysis using the strut-and-tie method. Here, concrete acts as a network of compression struts and tension ties.

The software breaks down tricky stress patterns into simpler design chunks. Engineers spot where they need extra reinforcement fast.

Primary features:

- Automatic strut-and-tie model generation

- Reinforcement detailing

- Code compliance checking (Eurocode 2, ACI 318)

- 3D visualisation of load paths

We find this super handy for precast concrete brackets and corbels. The software deals with both static and dynamic loads pretty well.

Typical workflow involves:

- Import geometry from CAD

- Define loads and supports

- Generate strut-and-tie model

- Optimise reinforcement layout

- Export detailed drawings

Universities often pick AStrutTie for teaching. The visual approach just makes it easier for students to see how forces move through concrete.

SimScale and Cloud-Based Approaches

SimScale takes bracket analysis to the cloud. You don’t need expensive computers or complicated installs—just open your browser.

The platform handles finite element analysis for structural, thermal, and fluid problems. Smaller engineering firms love the easy access.

Cloud advantages include:

- Unlimited computing power

- Automatic software updates

- Collaborative design reviews

- Pay-per-use pricing models

We’ve put SimScale through its paces on all kinds of brackets—from simple steel to complex aerospace parts. The results stack up well against old-school desktop tools.

Pricing structure:

- Community plan: Free (limited simulations)

- Professional: £75/month per user

- Team plans: £150/month per user

It also hooks up nicely with popular CAD tools like SolidWorks and Fusion 360. You can upload models straight in and get results in hours, not days.

Real-time collaboration means global teams can work together on bracket optimisation projects. That’s a lifesaver for companies with engineers spread out everywhere.

Applying Distributed Loads in Bracket Analysis

Distributed loads spread force across a surface instead of dumping it all on a single point. That makes them crucial for real bracket analysis. Modern software applies these loads with surface pressure and trigonometric patterns that mimic how things work in the real world.

Techniques for Load Application

Software gives us a few ways to apply distributed loads. The most common? Surface pressure—we set how much force hits the inside of mounting holes or contact areas.

COMSOL and ANSYS let us use trigonometric patterns. We can set loads as P0 cos θ, where θ is the angle from the load direction. That lines up with how pins and bolts actually send force into brackets.

Remote loads make complex setups easier. If we need torque and distributed force at once, remote loads let us set the total force, and the software figures out how to spread it out.

Most programs offer these options:

- Pressure loads on surfaces

- Force per unit area calculations

- Nodal force distribution for mesh elements

- Body loads for weight and acceleration

We can ramp up loads from 0.1 to 1.0 of full strength. Starting at 10% helps with convergence in tricky non-linear analyses.

Real-World Examples

L-shaped mounting brackets usually deal with uniform distributed loads on their top surfaces. We model these as pressure that stands in for the weight of equipment or whatever force it’s holding.

Steel brackets that hold up machine arms face bending loads in more than one spot. The software spreads these forces over contact areas, not just at a single node.

Automotive brackets get hit with dynamic loading from vibration and acceleration. We model these as time-varying distributed loads, matching the real frequencies in use.

Pin connections create concentrated loads, but we model them as distributed pressure around the hole edge. That avoids fake stress spikes you wouldn’t see in a real part.

Typical distributed load cases look like this:

- Equipment mounting: 500-2000 N/m²

- Vibration loading: ±200 N/m² cyclic

- Thermal expansion forces across surfaces

- Bolt preload spread around fastener holes

Evolutionary Structural Optimisation (ESO) in Bracket Design

ESO chips away weak material one step at a time to build stronger, lighter brackets. This method lets engineers design parts that use less stuff but still hold up.

Principles of ESO

ESO works by slowly removing material that doesn’t help carry the load. The software starts with a solid chunk and carves out little pieces over several cycles.

Each round checks how much stress hits every spot. Low-stress zones get the axe first. That makes holes and channels where material isn’t needed.

The process keeps going until we hit the best shape. Engineers can set ground rules for how much to remove and where to keep things thick.

Key ESO steps:

- Analyse stress in all parts

- Remove lowest-stressed elements

- Recalculate forces on what’s left

- Repeat until optimal

Modern ESO tools can add material back in if needed. This two-way approach stops us from over-trimming by mistake.

Optimisation for Weight and Strength

ESO helps us make brackets that are both light and tough. Weight cuts often land between 30-50% compared to solid blocks.

The software juggles different goals. Less material means lighter weight, but you don’t want to make the bracket flimsy. ESO finds that middle ground.

Engineers set constraint limits to steer the process:

- Maximum stress allowed

- Minimum safety factors

- Weight targets

- Size restrictions

Real-world examples show big gains. Truck cabin mounting brackets, for instance, have been optimised this way—they keep their strength and lose a lot of weight.

The final bracket shapes usually look a bit organic. Expect curves and channels that follow the stress paths. That helps the load flow through the material efficiently.

Vibration and Deflection Analysis of Brackets

Engineers look at how brackets handle vibrations and figure out their maximum deflection when loaded. These checks help prevent structural failures and keep brackets running safely.

Vibration Modes in Brackets

Every bracket has its own natural frequencies—spots where it vibrates with almost no effort. If outside forces match those frequencies, resonance hits and stress goes way up.

Modal analysis finds those key frequencies. We use finite element software like ANSYS or MATLAB to figure out where they land.

Key vibration characteristics include:

- First mode frequency (usually the one to watch)

- Mode shapes that show how the bracket deforms

- Frequency response at different loads

Random vibration analysis checks how brackets react to unpredictable forces. This approach uses power spectral density (PSD) to guess how the bracket will behave in real life.

Harmonic response analysis looks at steady vibrations at set frequencies. Engineers scan across the range to spot resonance peaks and stress hot-spots.

Heads up: Brackets running near their natural frequencies can shake themselves apart from amplified vibration.

Deflection Calculation Using FEA

Finite element analysis breaks the bracket into tiny pieces to calculate max deflection. Each piece acts a little differently, and the software adds them up for the big picture.

Static analysis finds deflection under steady loads. We add supports and loads, then let the software solve for displacement at every node.

Essential material properties:

- Young’s modulus (usually 200 GPa for steel)

- Poisson’s ratio (about 0.3 for metals)

- Yield strength to check if stress is too high

The results show displacement in x, y, and z. Maximum deflection usually shows up where the load hits or at unsupported edges.

Von Mises stress calculations go hand in hand with deflection checks. This helps us see if the bracket is deforming safely.

Mesh quality really matters. Tighter meshes at stress points give better results, but they eat up more computing time.

Comparative Evaluation of Leading Bracket Analysis Software

Picking bracket analysis software isn’t just about features—you have to weigh accuracy, ease of use, and bang for your buck. Let’s dig into what actually matters when choosing software, and how the price tag might swing your choice.

Criteria for Effective Software Selection

Accuracy is king when it comes to bracket analysis. Recent research shows big gaps between manual and automated systems. For example, 3Shape OrthoAnalyzer and Meshmixer usually beat automated tools like EasyRx for precision.

Manual vs automated processing is the main split. Manual software needs more know-how but gives you tighter results. Automated tools are quick and easy, but sometimes miss the mark on tough cases.

Software compatibility can make or break your workflow. Look for programs that handle STL files and fit with your scanner setup. CEREC Omnicam users, for instance, need software that works with their file types.

Processing capabilities jump around between platforms. Some are great at cleaning up artifacts, others get tripped up by tricky shapes. Think about what you see most in your work.

User interface design affects your day-to-day. Handy tools like “Remove Artifacts” in 3Shape or “Surface Lasso” in Meshmixer can speed things up and make training smoother.

Cost and User Experience Factors

Pricing models are all over the place in bracket analysis. Manual software like 3Shape usually means a big upfront license fee. Automated tools like EasyRx go with per-case pricing.

Training needs add to your real costs. Manual systems need more staff training, but you get more control. Plan for that extra time if you want the best results.

Processing speed changes depending on your system. Automated tools are faster but may need more quality checks. Manual work takes longer but often means fewer do-overs.

Technical support is a lifesaver when things go sideways. Big names like 3Shape have strong support teams, but some new automated tools might leave you hanging.

Scalability matters if your practice is growing. Per-case pricing works for low volume, but licenses pay off if you handle lots of cases. Run the numbers for your average month to see what fits best.

Future Trends in Bracket Software Analysis

Bracket software analysis keeps changing fast. Artificial intelligence now automates complex tournament structures, and cloud-based platforms let global esports teams collaborate in real time.

These new tools are shaking up the way we design, manage, and optimize competitive gaming tournaments.

Integration of AI and Automation

AI-powered bracket systems are taking over how we handle tournament fairness and participant matching. Machine learning algorithms dig into player performance data, past match results, and skill ratings to build balanced brackets automatically.

Smart Seeding Systems use predictive analytics to guess match outcomes and tweak seeding as needed. This shift reduces human bias and leads to more competitive matchups.

AI systems now monitor brackets in real time. When performance data shows an unfair advantage, the system flags it right away.

Key AI Features:

- Dynamic bracket rebalancing

- Performance-based seeding algorithms

- Automated fairness monitoring

- Predictive match outcome analysis

Tournament organizers say AI-assisted bracketing cuts complaints by 40% compared to old-school manual methods. The tech handles tricky situations like skill gaps and scheduling conflicts way better than traditional approaches.

Cloud Collaboration and Remote Analysis

Cloud-based bracket platforms let organizers work together from anywhere, no matter the time zone. Multiple staff members can access, edit, and monitor tournaments at the same time, and nobody has to worry about version conflicts.

Remote Tournament Management gives organizers the freedom to run events from anywhere with internet. That flexibility became essential during recent disruptions, and it’s still a game-changer for international competitions.

Everyone gets real-time data sharing, so bracket changes pop up instantly on all devices. Participants, organizers, and spectators see updates together, which helps cut down on confusion.

Cloud Platform Benefits:

- Multi-user editing capabilities

- Instant sync across devices

- Automated backup and recovery

- Scalable infrastructure for big events

Directors can now manage several events at once from a single dashboard. Cloud analytics also offer detailed insights into participant behavior, engagement, and ways to make tournaments flow better.

Frequently Asked Questions

Diving into bracket software analysis always brings up a bunch of common questions about strategies, tools, and methods. Let’s tackle the practical stuff that actually helps you with bracket predictions and tournament success.

What are the top strategies for predicting successful NCAA brackets?

The best bracket predictions mix statistical analysis with some strategy. We usually start by focusing on seeding patterns since higher seeds tend to win early rounds more often.

Smart Bracket software uses decision intelligence to spot gaps between team popularity and real winning odds. This helps you steer clear of emotional picks and stick to the data.

Here are a few things to consider:

- Team performance in conference tournaments

- Key player injuries or suspensions

- Historical matchup data between similar teams

- Road game performance over the season

Most top predictors spend extra time looking at 5-12 seed matchups. Those games are where you can spot upsets others might miss.

Could you share some insights on choosing the best bracket upset picks?

Picking upsets takes a careful look at seeding gaps and team momentum. We usually look for lower seeds that won their conference tournaments or finished the season on a hot streak.

The 5-12 matchup is always wild and offers great upset potential. Teams seeded 12th often play with nothing to lose and bring serious energy.

Watch for these signs when picking upsets:

- Strong defense from the lower seed

- Veteran players with tournament experience

- Higher seed struggling late in the season

- Coaches who know how to handle pressure

Try not to pick upsets just because of a team’s name. Stick to recent performance data and direct comparisons when you can.

How do experts make their March Madness bracket predictions?

Experts rely on advanced analytics and historical data for their bracket picks. We notice that pros use several data sources, not just one stat or metric.

Many experts turn to bracket management software that crunches thousands of data points automatically. These tools look at everything from shooting percentages to travel distances.

The most effective approach usually includes:

- Blending computer models with some gut feeling

- Giving more weight to recent performance than season averages

- Factoring in tournament experience and coaching history

- Checking team chemistry and injury reports

Experts rarely pick too many upsets in later rounds. They usually save those bold picks for the early games, where the odds make more sense.

Which tools are recommended for free bracket analysis?

Several free bracket analysis tools offer solid data for tournament predictions. We suggest starting with ESPN’s Tournament Challenge, which gives you basic stats and comparisons.

ESPN’s bracket tool has team stats, recent performance, and expert picks for free. You can also see how other users are picking each game.

Other good free resources:

- NCAA’s official tournament stats

- Team ranking sites with historical data

- Sports news sites with expert takes

- Social media accounts from verified analysts

For deeper analysis, you could try paid tools like Smart Bracket (about $5) or similar software. Those come with decision intelligence features that free tools usually skip.

What should one look out for when picking a Final Four bracket?

Final Four picks are a different beast than early round choices. We like to focus on teams with real tournament experience and strong coaching for these key games.

Look for teams that handle pressure well during the regular season. Conference tournament champs often ride that momentum deep into the tournament.

Critical factors for Final Four picks:

- Deep benches to handle fatigue

- Reliable free throw shooting under pressure

- Coaches with previous Final Four experience

- Balanced scoring from several players

Don’t go wild picking low seeds for your Final Four. Upsets happen early, but higher seeds usually make it to the last weekend because of their talent and depth.

How do the most successful bracket pickers evaluate their choices?

The most successful bracket pickers rely on systematic evaluation instead of just trusting their gut. You’ll often see them jot down their reasoning for each pick, hoping to spot patterns in how they decide.

Smart Bracket users usually land in the 90th percentile by sticking with data-driven approaches. They look for gaps between what the public thinks and how strong a team actually is.

These folks use a few key methods:

- They keep track of how accurate their picks are across different seed ranges.

- They analyze which upsets end up being the most profitable.

- They check which stats really seem to matter for success.

- They stack their results up against computer models just to see where they stand.

Top performers rarely let last-minute news shake their confidence. Instead, they trust their system and avoid scrambling to change picks at the eleventh hour.

By regularly evaluating their strategies, they spot any weak spots and tweak their approach after each tournament.